METASU YC process

High corrosion resistance is achieved by applying a zinc-aluminum composite rust-resistant coating, enabling the service life extension of key parts for our customers.

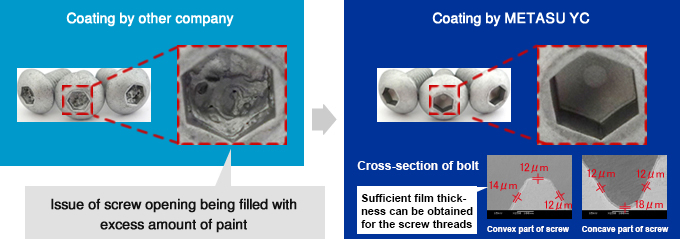

Superior consistent coating performance prevents recess-fill problems

The excellent wettability and thixotropic performance of METASU YC create consistent coating and greatly reduces recess of the head

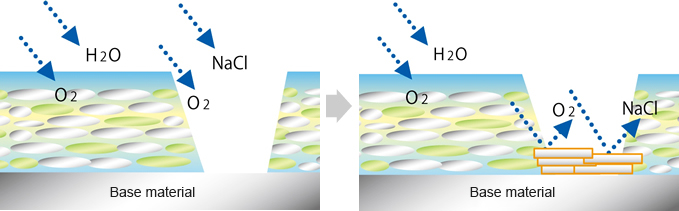

Self-healing feature makes it resistant against scratch and maintain consistent high corrosion resistance

A unique formula and technology make it highly resistant to corrosion even when the surface is scratched or damaged.

-

0hr

-

1500hr

-

2500hr

※ SST test is performed after an impact wrench is used for 3 cycles of "tightening and loosening"

Each corrosion-resistant performance can be tuned by selecting the processing conditions.

| 1C1B | 2C2B | 2C2B + 1T |

|---|---|---|

| SST 500hr | SST 2,000hr | SST 3,000hr |

C:METASU YC-B (base coat)

B:Baking (baking)

T:METASU YC-T (top coat)

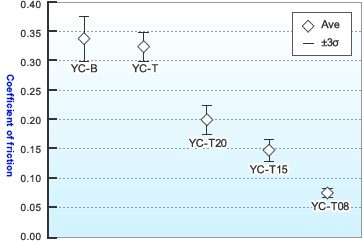

Various types of top coats for different coefficients of friction

A lineup of top coats catered for each automobile maker

Top coats lineup

| Product Name | Color | Coefficient of friction |

|---|---|---|

| YC-T | Clear | 0.30 - 0.35 |

| YC-T20 | Blue | 0.18 - 0.22 |

| YC-T15 | Clear | 0.14 - 0.17 |

| YC-T08 | Red | 0.077 - 0.085 |

※ Possible to adjust the coefficient of friction to outside of its range. Feel free to make an inquiry.

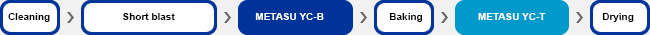

Fabrication process and production capacity

Production capacity: 22ton/month and 8h/day *production capacity is being increased sequentially

●Fabrication process

Inquiry on customizable processing

Feel free to contact us if you have any queries regarding the specifications, delivery schedule and costs of the customizable processing.